With over sixty years of experience, we are stepping into a new era — one where we simplify the entire process for our customers.

We manage every stage internally — from mold design and construction to die casting, from machining to quality control.

We offer high-pressure die casting (HPDC) and semi-solid forging (SSF) technologies, along with advanced 3D printing and metal deposition services.

With our Design Sprint Week ©, we define the design, optimize every detail, and guide the customer all the way to production.

In short: we take care of everything — making the process easier and getting you to market faster.

Arrive with a project,leave with a product— and a plan

Ten months for a prototype

Too long for a market that changes every week.

Innovation, timing and complexity intertwine every day.

Each change — a tolerance, a requirement, a supplier — can trigger rework, repeated tests, and weeks of delay.

The result? Milestones shift, start-of-production slips, costs rise and opportunities disappear

Our promise:10 months in 1 week

Your project becomes the top priority of a multidisciplinary team, led by a figure who ensures method, rigor and results.

We compress into five days what today takes months:

- Project analysis and technical alignment;

- Real-time review with the full team;

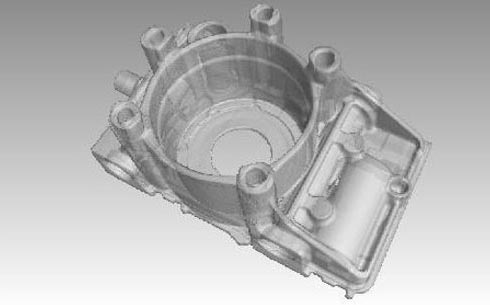

- 3D metal prototype, already aligned with the production process;

- Validation and industrialization plan, ready for manufacturing.

Design Sprint Week ©

The new Metalpres Donati service designed to reduce development time, refine projects, and deliver prototypes ready for series production.

Every month you wait is a month lost.

Discover how to accelerate your next project.

Accelerate development and reduce waste

Speed.Precision.Sustainability.

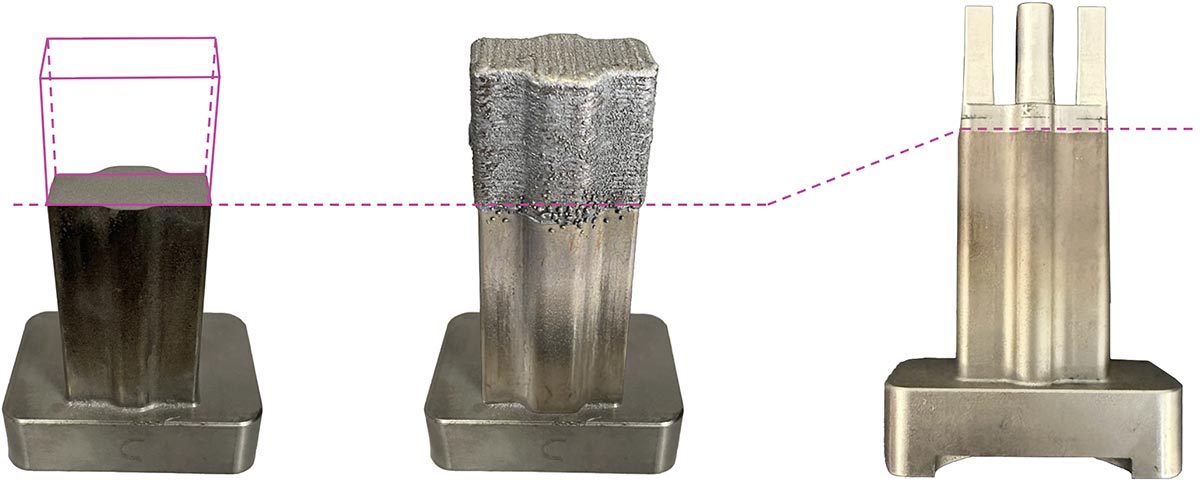

We work with two metal 3D-printing technologies, including a powder-bed system that mainly uses aluminium.

This allows us to produce prototypes and functional components extremely quickly, enabling customers to test and optimize their designs before die casting.

The result? Less waiting, lower costs, better products.

Additive manufacturing is also a concrete step toward sustainability: only what is needed is produced, with optimized use of energy and materials.

Every piece is born optimized — no waste, no scrap.

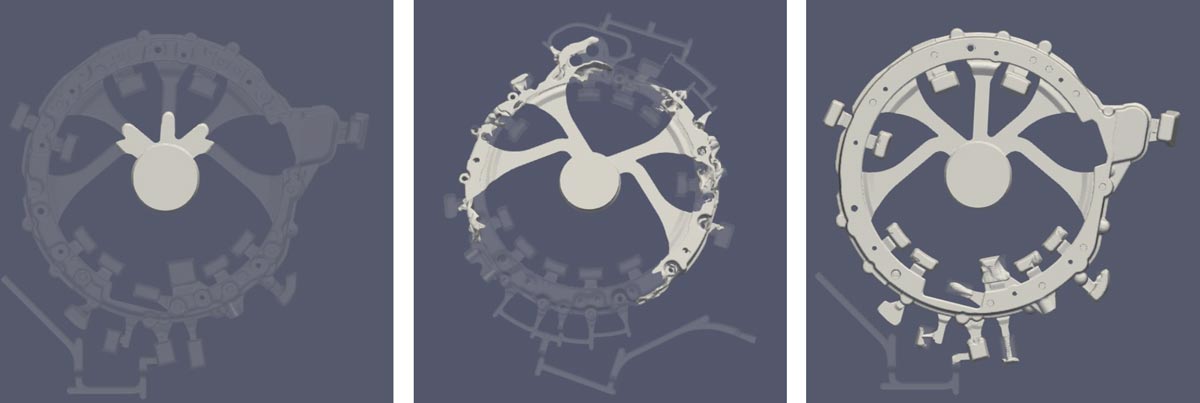

Powder Bed Fusion

Powder Bed Fusion is a metal 3D-printing technology that uses a laser or electron beam to selectively melt metal powder, layer by layer.

The result is a component with complex geometries, high dimensional accuracy and excellent mechanical properties, comparable to metals produced through traditional processes.

| Material | AlSi10Mg |

| Maximum printable size | 250 x 250 x 300 h (mm) |

| Geometric accuracy | ±0,2 - 0,4 mm |

| Hardness | 90 HB |

| Elongation | 5,5 % |

| Tensile strength | 400 MPa |

| Yield strength | 245 MPa |

| Roughness | Rz |

Commercial offers

Every proposal begins with an in-depth technical dialogue and a careful analysis of market requirements. The result is a tailored, transparent and value-oriented offer.

A partner to grow with

We aim to be a partner with whom to share strategies, experience and technical competence.

Thanks to our long-standing know-how, we bring to each project proven solutions and practical knowledge — the kind that makes every component more efficient, reliable and ready for production.

Our relationships with customers are based on three principles: competitiveness, flexibility and speed.

We stand beside our partners to face every challenge, applying design-to-cost and design-to-process logic to create high-performing products aligned with market expectations.

Innovationborn from detail

Where value meets tradition

Every project begins with a conversation: we listen, analyse and build together the most effective path.

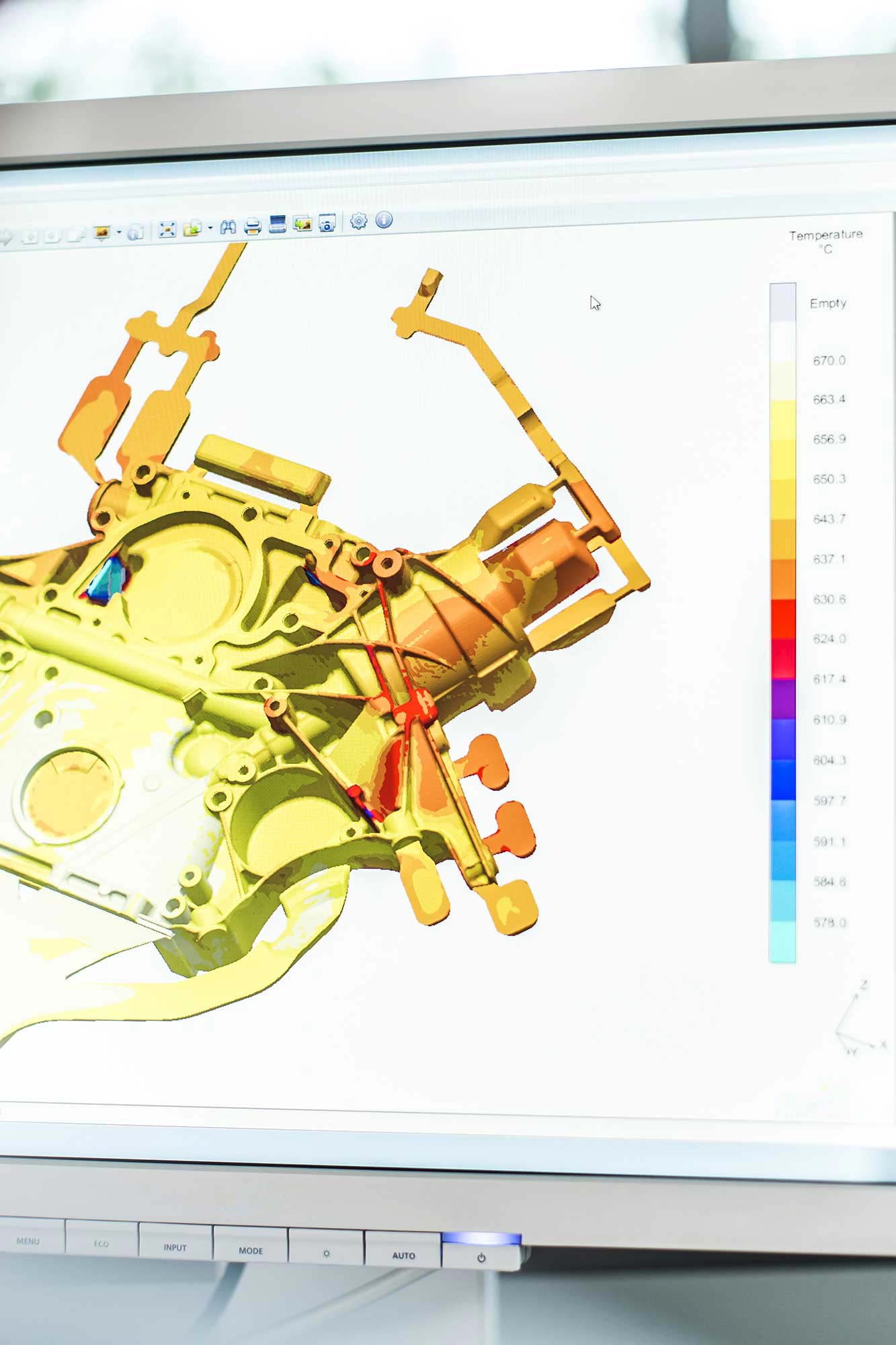

Mould design is a strategic phase — efficiency and quality of the entire production process depend on it.

Each detail is studied with precision and simulated using advanced software.

But technology alone is not enough: we invest in people, in their growth and curiosity.

We believe in young talent and in the value of knowledge that is shared and renewed every day.

Research & Development

From virtual simulation to physical verification, every step is guided by precision and experience.

We design to anticipate potential issues and transform ideas into tangible, ready-to-industrialize solutions.

Control.Precision.Speed.

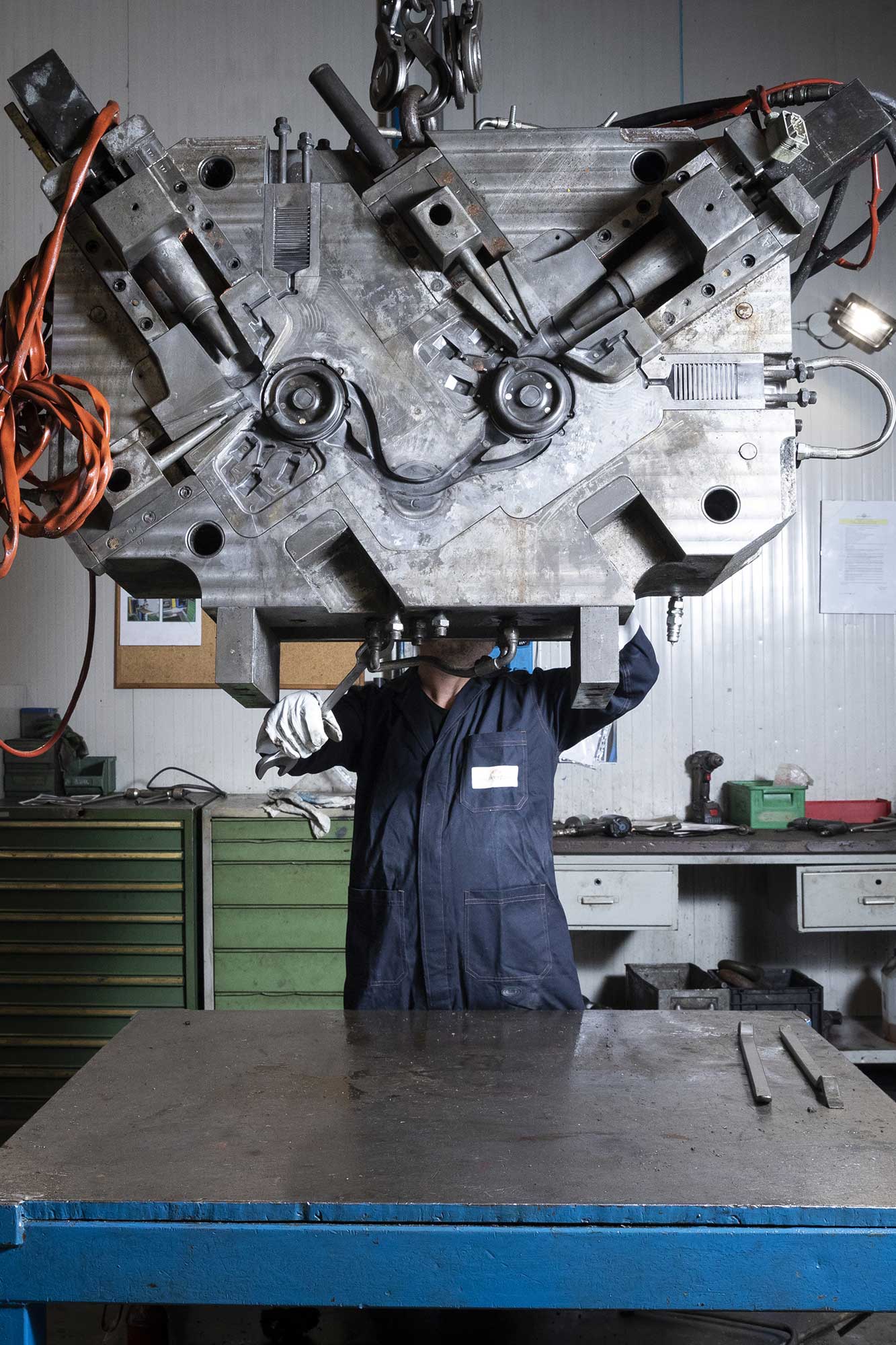

Tool shop

All the moulds used in Metalpres Donati production are designed and manufactured directly in-house. Maintenance of die-casting moulds throughout their entire lifecycle is handled by the same department.

This allows us to:

- shorten development and optimisation times;

- keep costs under control;

- increase operational flexibility.

The production heart of Metalpres Donati

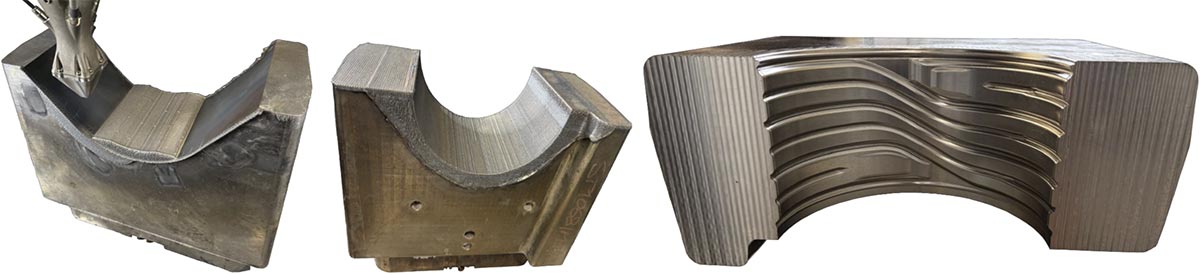

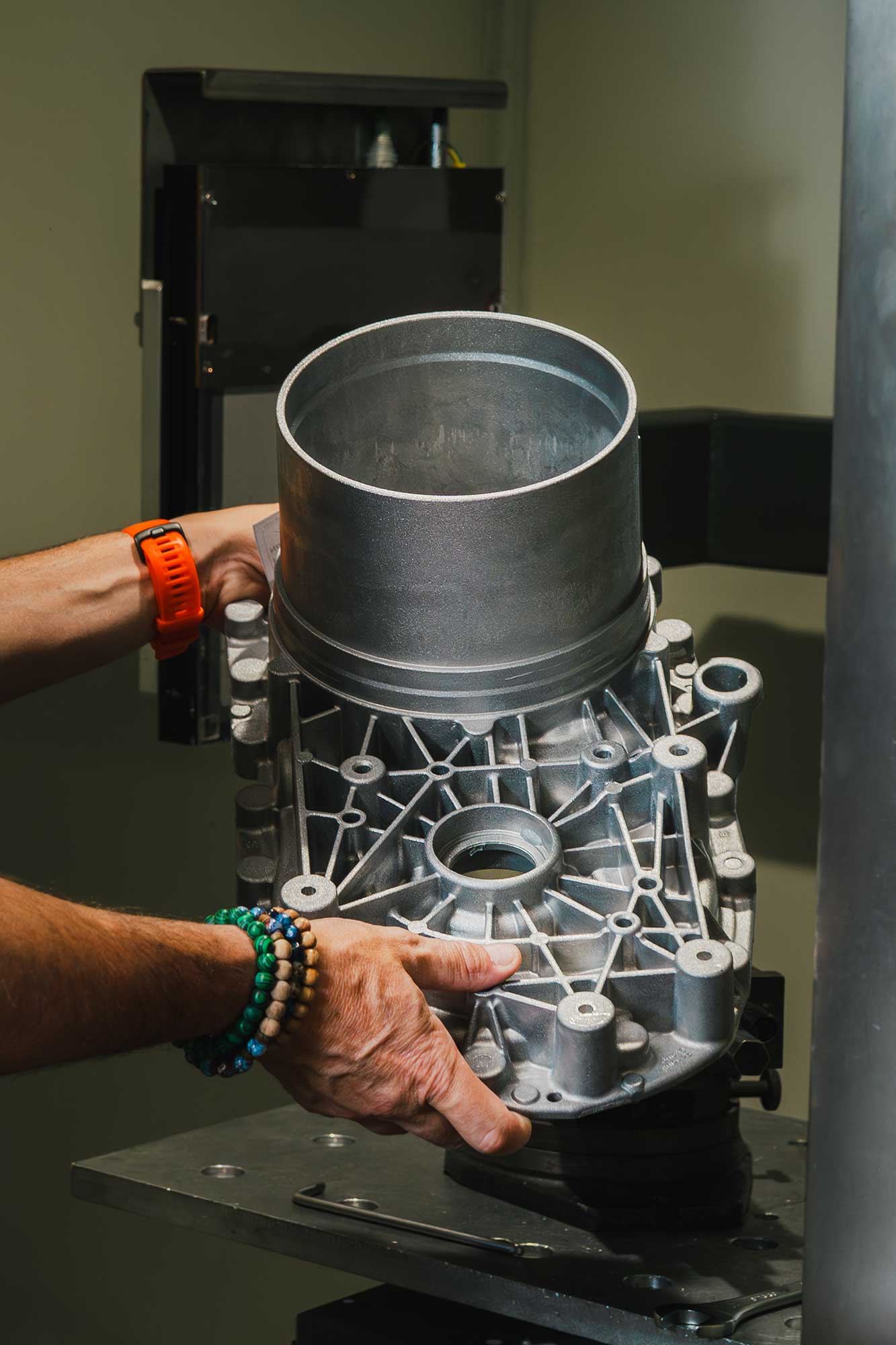

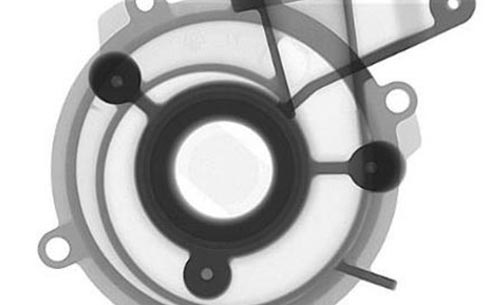

Precise.Light.Integral.

The new generation of components. Precise, lightweight and naturally flawless.

Aluminum processed in a semi-solid state for a compact microstructure, free of porosity and with superior mechanical performance.

A proprietary — patented — technology that combines the freedom of die casting with the strength of forging.

For high-reliability structural components, where weight, strength, and quality make no compromises.

Compact structure, superior fatigue strength.

The Semi Solid Forging® process operates in a semi-solid state, controlling solidification to eliminate any internal porosity.

It’s the choice of those who design with the goal of ensuring consistent quality and process repeatability, even in the most demanding applications.

| SEMISOLID FORGING Alloy 6082 * | SEMISOLID FORGING Alloy 21100 * | |

| Rm | 390 | 440 |

| Rp02 | 310 | 390 |

| A% | 10 | 14 |

| HB | 130 | 145 |

* Values after T6 Heat Treatment

Strength.Control.Series.

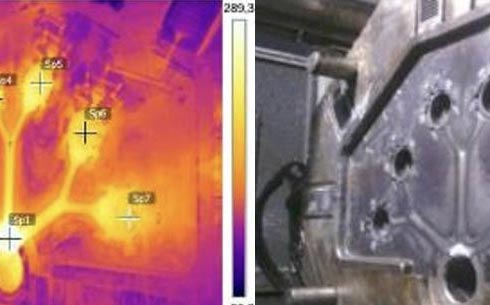

High Pressure Die Casting

To guarantees high volumes, dimensional precision and quality consistency.

From metal to product

With 16 presses up to 2,200 tons, the foundry is the production heart of MPD: competitive volumes, stable quality and maximum flexibility.

Technology. Industry 4.0 digital processes and native 5.0 presses ensure thermal stability, operational safety and reduced scrap.

Materials. We use high-performance alloys for automotive and industrial applications, optimized for strength and casting fluidity.

Quality. Each stage is digitally tracked to guarantee conformity and process repeatability.

People & Sustainability. Automation reduces manual work and enhances human skills, making production more efficient, safe and sustainable.

Foundry data

Our strategy includes the continuous renewal of presses, in line with Industry 4.0 and 5.0 standards.

Alloys:

EN AC 43400 | EN AC 44300

EN AC 46000 | EN AC 46100

EN AC 46500 | EN AC 47100

Installed capacity

10

Millions kg / year

From 530 to 2,200 tons of clamping force

| Brand | Island |

| BUHLER | 1 – 530/1 |

| BUHLER | 2 – 660/1 |

| ITALPRESSE | 3 – 1000 |

| STP | 4 – 850 |

| MAICO | 5 – 1100 |

| OMS | 6 – 1150 |

| BUHLER | 7 – 530/3 |

| BUHLER | 8 – 900 |

| BUHLER | 9 – 660/3 |

| OMS | 10 – 800 |

| FRECH | 11 – 830 |

| ITALPRESSE | 12 – 1650 |

| OMS | 13 – 2200 |

| OMS | 14 – 1850 |

| FRECH | 15 – 640/1 |

| FRECH | 16 – 640/2 |

Repair,don't replace

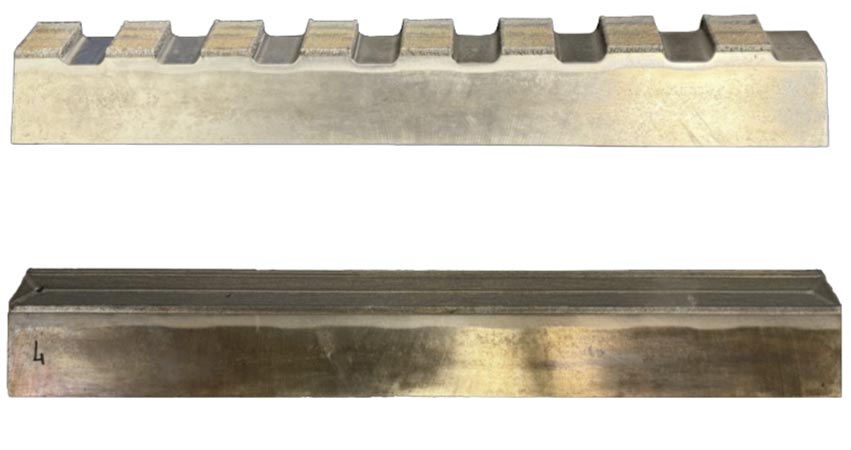

Material deposition on steel only where needed

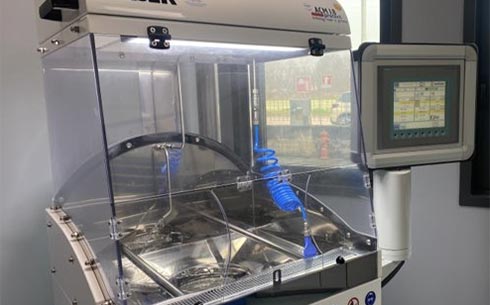

In addition to manufacturing new components, we regenerate existing metal parts through advanced coatings applied by laser cladding, adding customized functionality.

Instead of starting from scratch, we give new value to what you already have — reducing cost and waste, and making your business more sustainable and competitive.

3D printing and laser cladding: solutions to extend component life, cut costs and eliminate waste.

Benefits

- Significant reduction of machining waste;

- Physical and mechanical properties equal to or higher than the base metal;

- Short production times;

- Cost savings;

- Lower need for stock and storage space.

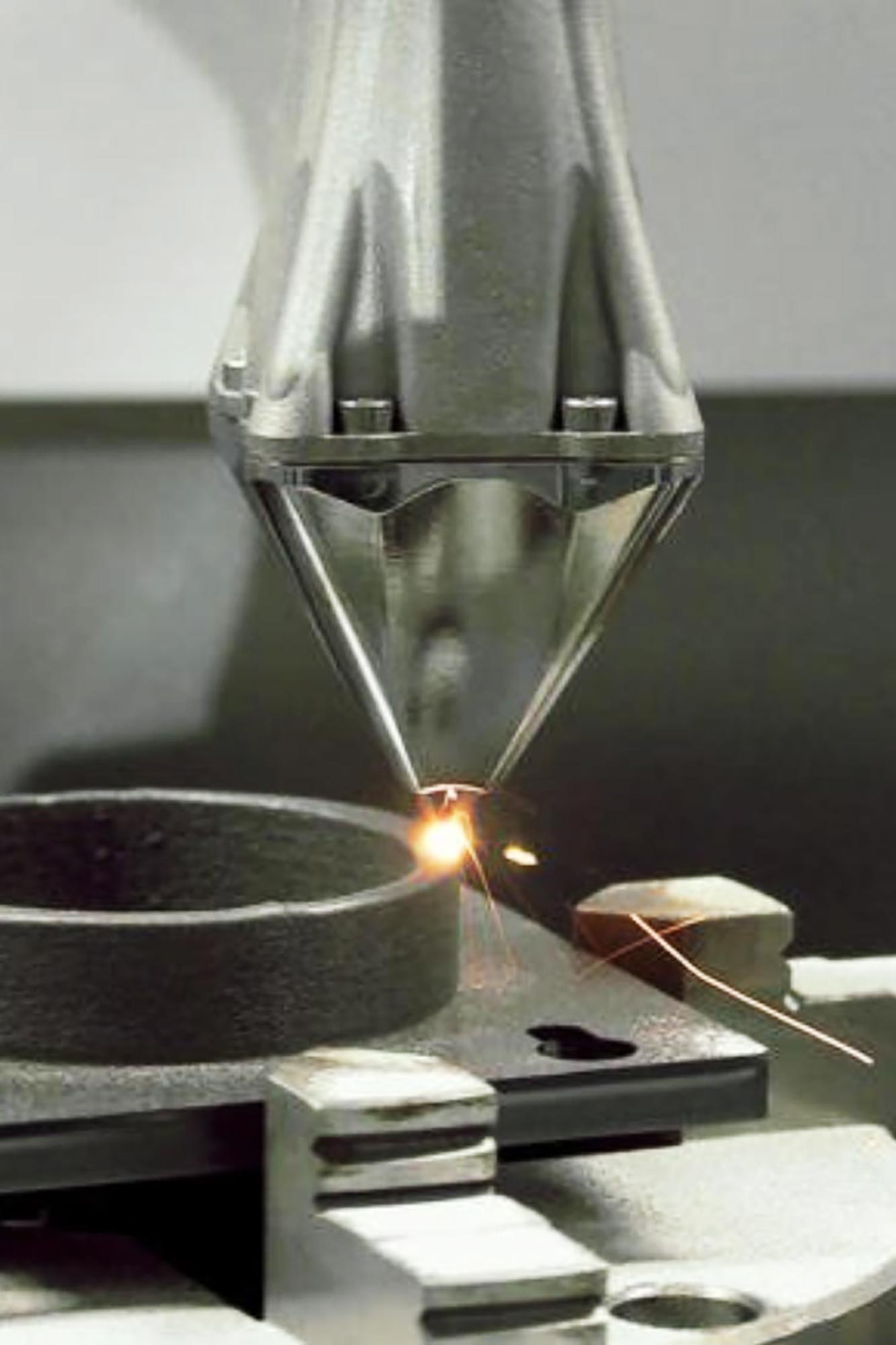

Direct Energy Deposition

Directed Energy Deposition uses a laser beam to melt the applied metal powder, creating a new layer of material perfectly bonded to the original surface.

Case study #1

Tire-cutting blades

Thanks to laser cladding, the blades were regenerated and reinforced, ensuring longer life compared to the original parts.

Case study #2

Foundry mold restoration service

By applying laser cladding, worn areas of the mould can be repaired, extending its lifetime and reducing production downtime.

The human eye behind mechanical perfection

Precision born from motion

Technology and human expertise merge in a continuous process of control and refinement.

Machines ensure minimal tolerances, while operators guide each phase with attention and sensitivity.

Here the part becomes ready for its final purpose — precise, reliable, flawless.

High productivity, consistent quality and full traceability: our standards.

Installed capacity

14

Millions pcs / year

26 machines installed

| Brand | Spindle | Quantità |

| MAKINO | 1 spindle | 1 |

| KITAMURA | 1 spindle | 1 |

| CHIRON | 2 spindles | 13 |

| CHIRON | 4 spindles | 1 |

| TECNOTRANSFER | 10 stations | 2 |

| GNUTTI TRANSFER | 10 stations | 1 |

| SW 4 AXES | 2 spindles | 2 |

| SW 5 AXES | 2 spindles | 1 |

| FANUC | 1 spindle | 3 |

| EMAG LATHE | 1 spindle | 2 |

| BIGLIA LATHE | 1 spindle | 1 |

Our distinctive mark

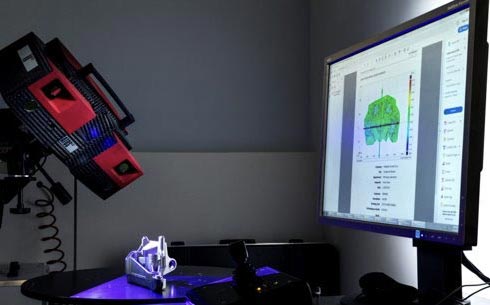

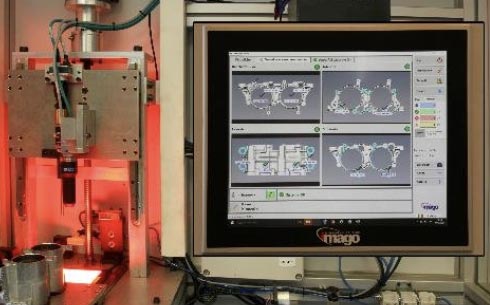

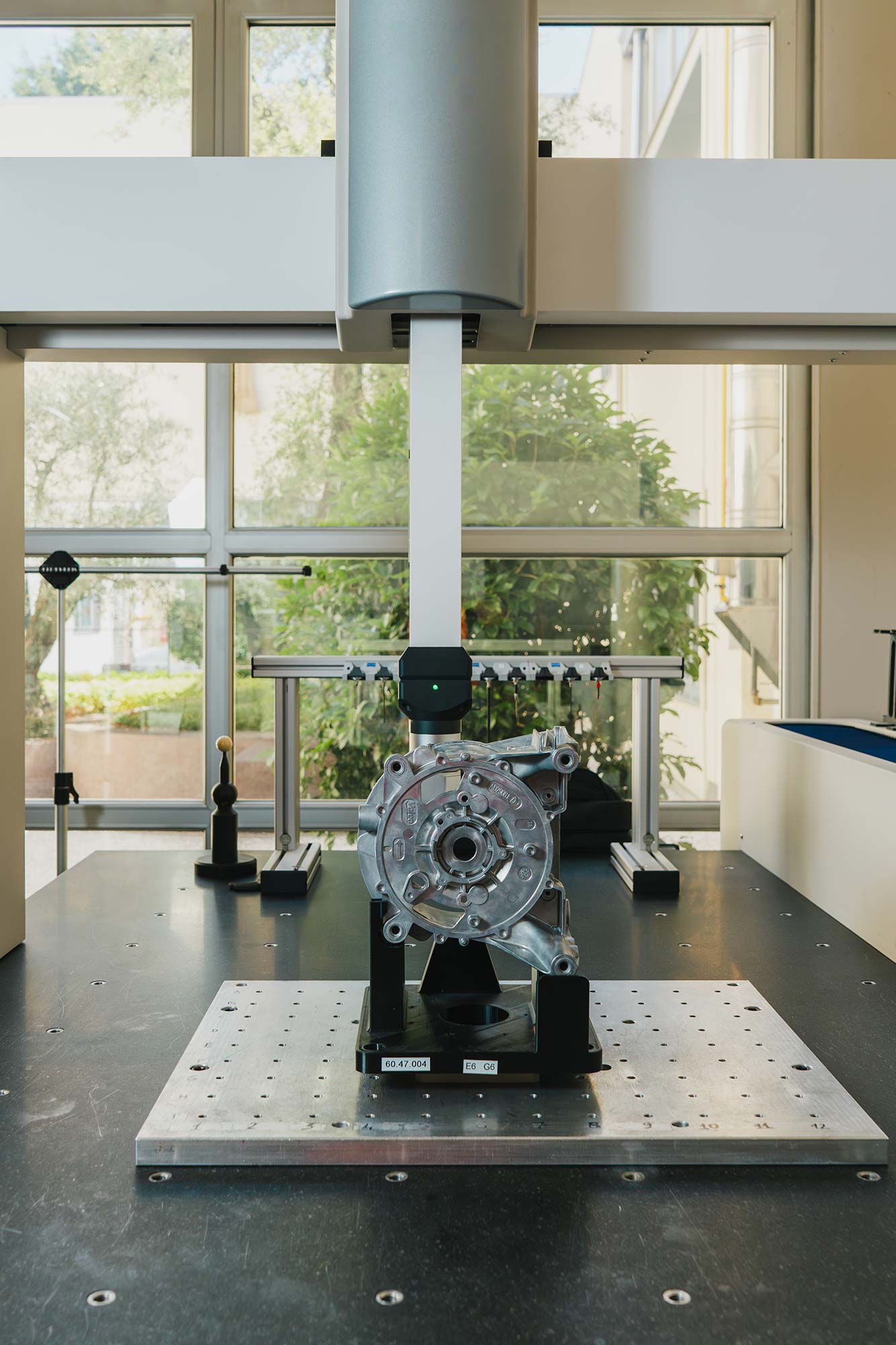

Quality is our mindset

In aluminium die casting, precision and reliability are not optional — especially in automotive.

Every part carries responsibility: safety, durability, consistent performance.

We invest in inspection technologies, training and processes that prevent errors before they occur.

For us, quality is built at every stage — from design to casting, to machining.

Being a reliable partner means guaranteeing continuity and full traceability over time.

Quality control equipment

Foundry

IATF 16949:2016

ISO 14001:2015

ISO 45001:2018

ISO 50001:2011

Quality control equipment

Machining

On time.Always.

Precision in motion

Every component leaving our departments carries with it the value of work performed with care and accuracy.

That’s why logistics is not a final step, but the point where care, control and reliability meet.

We handle every movement attentively, trace each route and ensure that every part reaches its destination in perfect condition — ready for machining or assembly.

Our monitoring systems let us know exactly where every batch is, at any moment.

Our punctual deliveries enable our customers to keep their processes running seamlessly — confident that what’s needed arrives precisely when it’s needed.

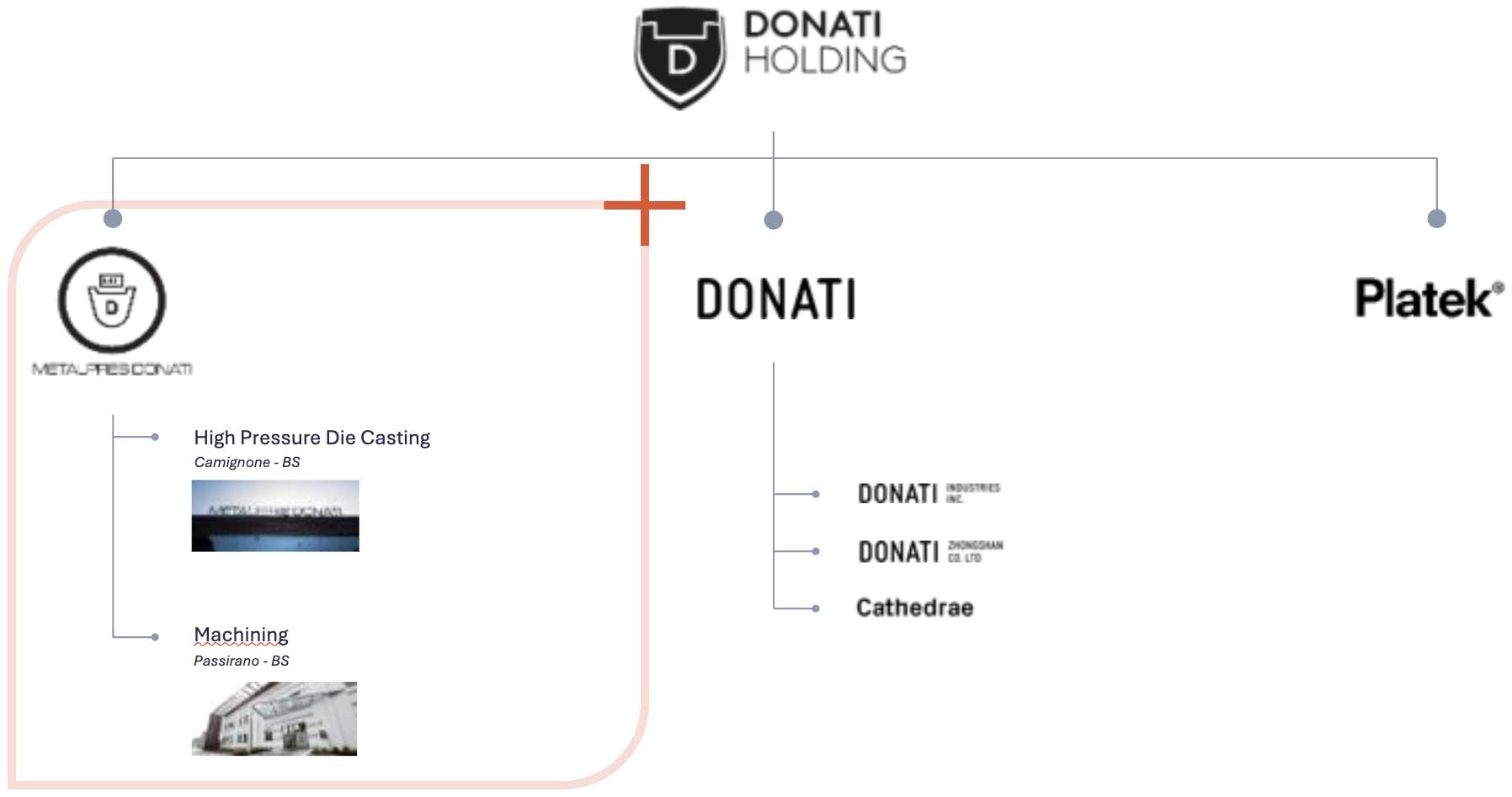

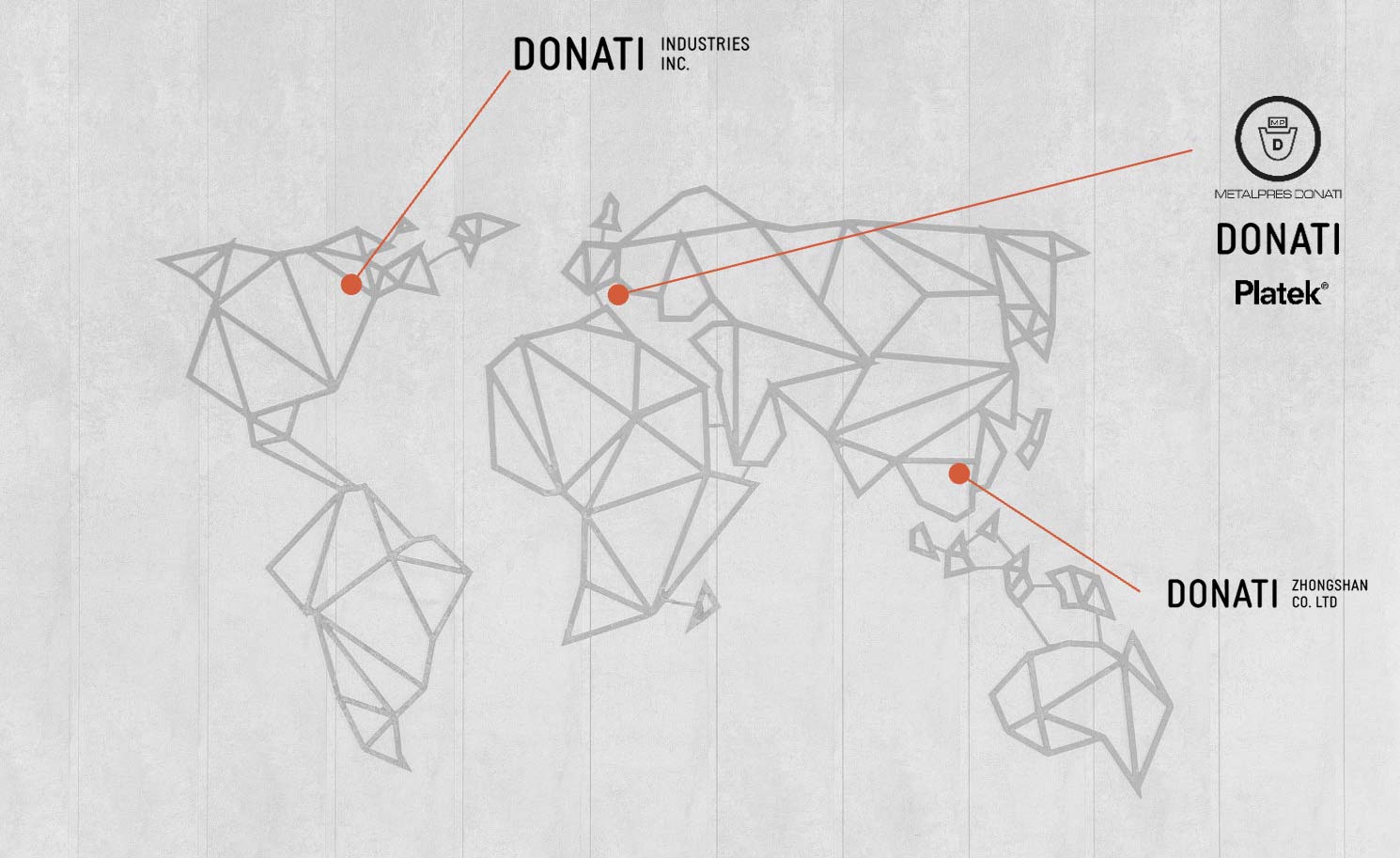

Who we are

At Metalpres Donati we radically innovate processes and organisation, driven by the ambition to become an international benchmark.

We enhance the value of recycled materials and apply advanced technologies to improve quality and efficiency, reducing environmental impact and creating value for employees, customers and the community.

Our history

Metalpres Donati was founded in the 1950s from the vision of Luigi Donati.

In an Italy racing toward industrialisation, we built our reputation on the quality of our supplies and the reliability of our relationships.

Over the years we expanded our skills and technologies, opening the way to more complex sectors and international partnerships.

Today we combine experience and innovation to simplify the entire process for our customers.

We invest in recycled alloys, sustainable processes and efficient energy systems, because for us, innovation also means responsibility.

A journey of seventy years with one direction: growing together with our customers, making every project faster, more precise and more sustainable.